Welcome to dB Noise Reduction

- Home

- Line of Products

- Technical data and specifications

- Resources

- Contact Us

- Home

- Line of Products

- Technical data and specifications

- Resources

- Contact Us

For other customized silencer designs, please contact us and we will be happy to assist you.

Up to 225° F

Up to 6,000 fpm (Model 521)

Over 6,000 fpm (Model 522)

-30" wg to +120" wg (Model 521)

-120" wg to +120" wg (Model 522)

From 12" ID to 120" ID (standard)

Larger sizes available

8" for flanges less than 4"

10" for flanges 4" and larger

+/- 0.5"

Up to 600 lbs (standard sizes)

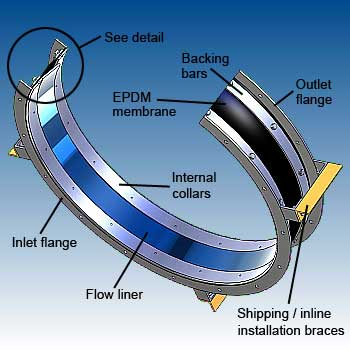

Carbon steel flanges, backing bars and flow liner (if supplied), zinc plated backing bar hardware and EPDM flex membrane

Stainless steel flanges, backing bars, flow liners and hardware available

Galvanized construction also available

Alkyd, enamel, high heat, inorganic zinc, epoxy and polyurethane