Welcome to dB Noise Reduction

- Home

- Line of Products

- Technical data and specifications

- Resources

- Contact Us

- Home

- Line of Products

- Technical data and specifications

- Resources

- Contact Us

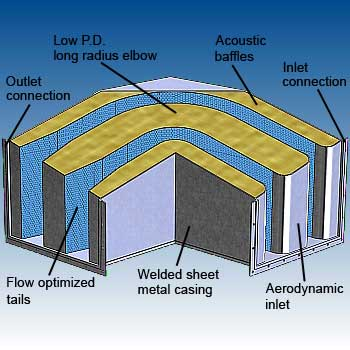

Alternative construction - Model 123 industrial grade, all welded construction

Alternative construction - Model 123 industrial grade, all welded construction

For other customized silencer designs, please contact us and we will be happy to assist you.

Up to 400,000 acfm

Up to 30" wg

Up to 250° F

From 24" X 24" X 36" ctr-line length

to 120" X 120" X 120" ctr-line length

(modules provided in banks for fast site assembly)

Up to 1,500 lbs per module

Mill galvanized (standard). Stainless steels and aluminum available

20 ga to 16 ga welded sheet metal casings with 22 ga acoustic baffles

Alkyd and enamel finishes available